Menu

Latest News

The Best Products

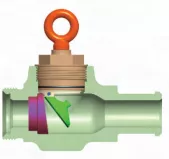

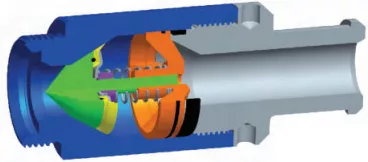

Check Valve

Product Overview

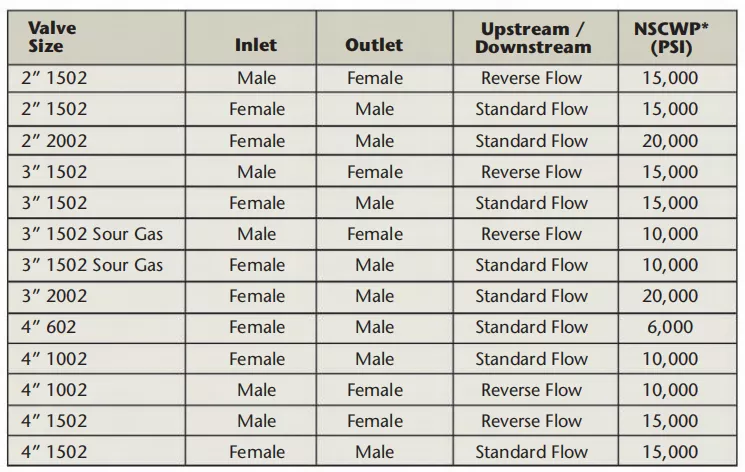

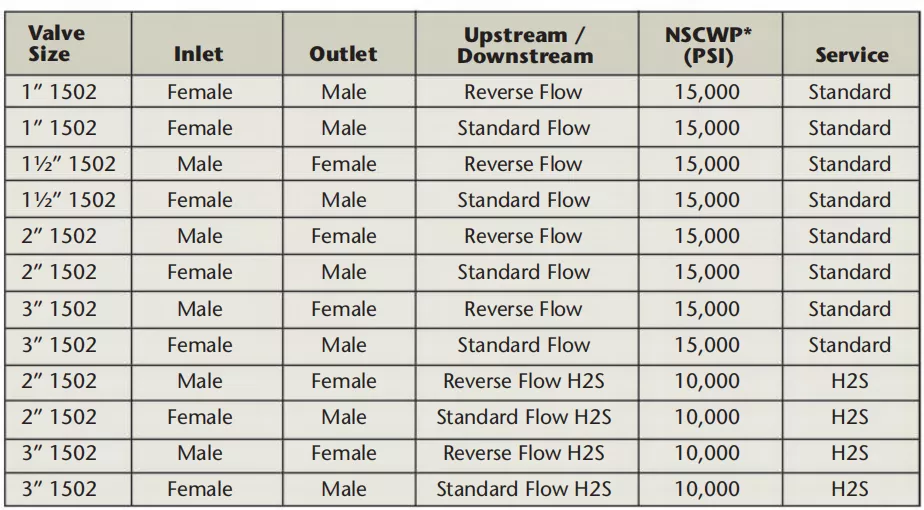

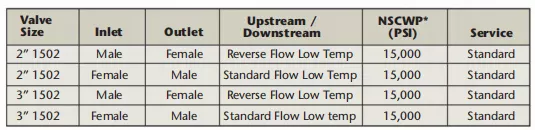

Our high-strength steel check valves are precision-manufactured to exacting tolerances for demanding well service operations, including acidizing, fracturing, cementing, and energized fluid handling. Available in clapper (2"-4"), dart (1"-3"), and CO2/nitrogen (2"-3") styles, these valves deliver unmatched reliability in corrosive and high-abrasion environments.

Key Features & Benefits

- Superior Durability

- Materials: Forged from solid high-strength steel for maximum abrasion resistance and structural integrity.

- Coatings: Choose between standard or superior abrasion/acid-resistant coatings (e.g., tungsten carbide) to extend service life in harsh conditions.

- High-Pressure Performance

- Working Pressure: 6,000–20,000 psi, ideal for well stimulation, hydraulic fracturing, and sour gas applications.

- Design Variants:

- Wing-Ahead (Standard Flow): Optimized for minimal pressure drop.

- Thread-Ahead (Reverse Flow): Enhanced sealing for backflow prevention.

- Industry-Leading Configurations

- Clapper Valves: Precision-sealed for rapid response in high-flow systems.

- Dart Valves: Compact design for space-constrained installations.

- CO2/Nitrogen Valves: Specialized for energized fluid control.

- Compliance & Certifications

- Meets API 6A, API 6D, and NACE MR0175 standards for oilfield and corrosive service.

Why Choose Our Check Valves?

- Widest Selection: The most comprehensive line of check valves for well service, with customizable coatings and connections.

- Low Maintenance: Engineered for self-cleaning seats and leak-free operation, reducing downtime.

- Global Proven: Trusted by operators in North America, Middle East, and offshore drilling.

CTA: Contact us for technical specs, bulk pricing, or custom configurations—engineer your flow control solution today!

Previous: Emergency Relief Valve