Menu

Latest News

The Best Products

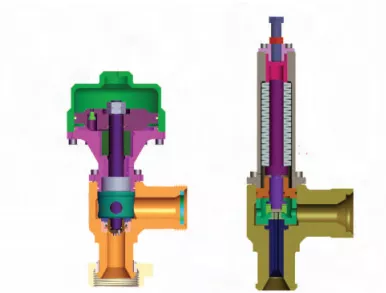

Emergency Relief Valve

Product Overview

Our Emergency Relief Valves (ERVs) provide critical over-pressure protection for reciprocating pumps, treating lines, pressure vessels, and high-pressure equipment across oilfields, refineries, and chemical plants. Engineered to handle extreme conditions (1,000–20,000 psi), these valves automatically activate when system pressure exceeds preset limits, then snap shut when safe levels are restored—ensuring continuous operational safety without manual intervention.

Key Features & Competitive Advantages

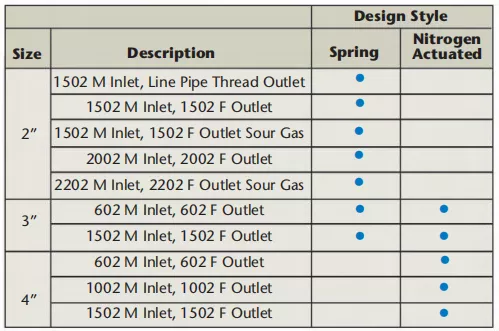

- Versatile Activation Systems

- Multi-Trigger Options: Choose from spring-operated, nitrogen-actuated, or rig air-activated mechanisms for flexible integration with your existing systems.

- Externally Adjustable: Fine-tune pressure settings easily without disassembly (unlike shear valves requiring nail triggers).

- High-Performance Design

- Flow Capacity:

- 2” Spring Model: 150 GPM

- 3” Spring Model: 430 GPM

- 3”/4” Back Pressure ERV: 750 GPM

- 3”/4” Unloading Valve: 1,000 GPM

- Scalable Solutions: Combine multiple valves (set within 10% pressure tolerance) for higher flow demands—e.g., three 2” valves (400 GPM) vs. one 3” valve.

- Flow Capacity:

- Durability & Compliance

- Materials: Corrosion-resistant alloys (standard and sour gas service models available).

- Certifications: Meets API 526, ASME Section VIII, and NACE MR0175 for harsh environments.

- Remote Control Panel

- Safely adjust nitrogen-actuated valves from a distance during operations, reducing worker exposure to hazardous zones.

Why Choose Our ERVs?

- Cost-Efficient: Optimize CAPEX with modular valve combinations (e.g., two 2” valves ≈ one 3” valve cost).

- Low Maintenance: Self-cleaning seats and rugged construction minimize downtime.

- Global Proven: Trusted by upstream/midstream operators in North America, Middle East, and offshore applications.

Technical Specifications

| Model | Size | Max Pressure | Flow Rate | Actuation Method |

|---|---|---|---|---|

| Standard ERV | 2”–4” | 20,000 psi | 150–1,000 GPM | Spring/Nitrogen/Air |

| Sour Gas ERV | 3”–4” | 15,000 psi | 750 GPM | NACE-compliant |

CTA: Contact us for custom configurations, bulk pricing, or technical support—engineer your safety solution today!

Previous: Hammer Union

Next: Ground Safety Valve